Advanced Automation Solutions for Modern Manufacturing #

Victor Taichung offers a diverse range of automated integration systems designed to streamline manufacturing processes, enhance productivity, and address the evolving needs of the machining industry. Below is an in-depth look at our key automation solutions and their unique features.

Collaborative Robot Arm: Simplifying Automation #

Vturn-A200 Horizontal Lathe + Collaborative Robot Arm

- Mobile robot cart enables quick installation, flexible deployment, and convenience.

- Collaborative robot arm allows for safe human-robot interaction without the need for safety fences, meeting regulatory standards.

- User-friendly operation reduces training time for operators.

- Capable of clamping multiple workpieces simultaneously, minimizing loading and unloading time.

System Components:

- Vturn-A200 Horizontal Lathe

- Collaborative Joint Robot Arm

- Material Platform

Vturn-S20 Horizontal Lathe + Gantry Robot #

To accommodate various processing requirements, the Vturn-S20 is available with Z-axis travel options of 400mm and 600mm. Its self-developed turret, driven by a servo motor, ensures stable tool positioning and operation. With a maximum workpiece diameter of 600mm, it is ideal for large workpiece machining. The conveyor belt can be configured for rear or side output, optimizing plant layout for automation.

Gantry Robot Features:

- Equipped with a CCD visual positioning system for rapid and easy automated line changes.

- Positioned above the machine, it does not interfere with operator tasks.

- Enables 24/7 automated operation, addressing labor shortages.

System Components:

- Vturn-S20 Horizontal Lathe

- Gantry Robot

- CCD Visual Positioning System

- Automatic Lifting In/Out System

Vturn-S20 Horizontal Lathe + Gantry Robot

Vturn-S20 Horizontal Lathe + Gantry Robot

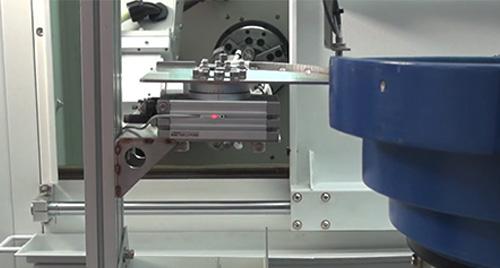

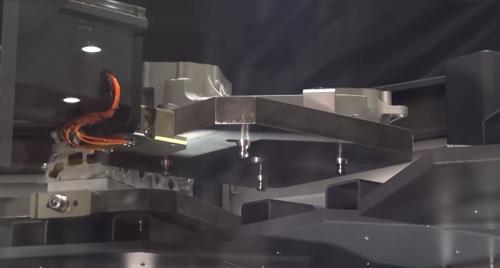

Gantry Robot System - Image 1

Gantry Robot System - Image 1

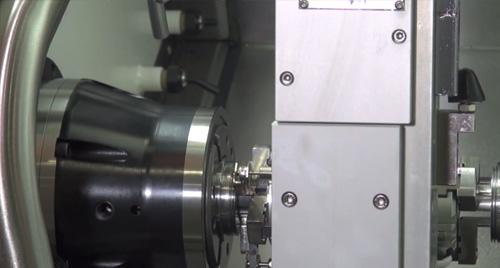

Gantry Robot System - Image 2

Gantry Robot System - Image 2

Vturn-F26 Fighter Lathe + Collaborative Robot Arm #

With rising environmental awareness, increasing costs, and the trend toward small-batch, diverse orders, the machining industry faces new challenges. The Vturn-F26, known for its high cost-performance and stability, helps manufacturers adapt to these demands.

System Components:

- Vturn-F26 Fighter Lathe

- UR Collaborative Robot Arm

- Tool Wear Monitoring System

- Equator 300 Off-Machine Measurement System

High-Performance Automated Processing System (Series 1): Two Small Lathes Vturn-NP16 + Robot Arm #

- Balances machining processes for parts A and B, improving production efficiency by up to 50%.

- Integrates automatic measurement correction feedback to maximize machine utilization.

- Two machines share a measuring instrument and material supply table, reducing investment costs.

- Achieves high production efficiency with minimal footprint and investment.

Process Overview:

- First Process: Machining inner/outer diameters, C-axis drilling, and tapping.

- Second Process: Machining inner/outer diameters, internal gear shaping, external diameter rolling, with robot-assisted off-machine measurement.

System Components:

- Two Vturn-NP16 Machines

- Elite Two-on-Two Automated Processing System (Gantry Robot x2, Off-Machine Measurement System: Marposs x1, Finished Product Robot x1, Automatic Material Supply Table x2)

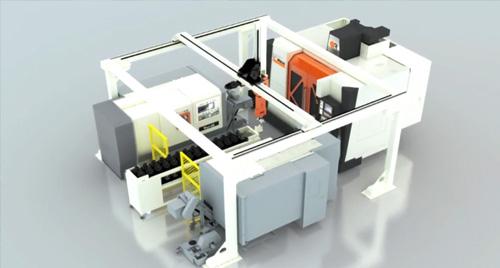

Regional Type Elbow Joint Robot Flexible Processing Unit #

- Features eight axes, offering greater cost-effectiveness than standard six-axis robots.

- Maximizes usable floor space within the system area.

- Requires less plant height compared to gantry robots.

System Components:

- Vturn-20E Lathe x2 + Vcenter-P106 Machining Center

- Regional Type Elbow Joint Robot

- Automatic Material Supply Table

- Workpiece Flipping Station

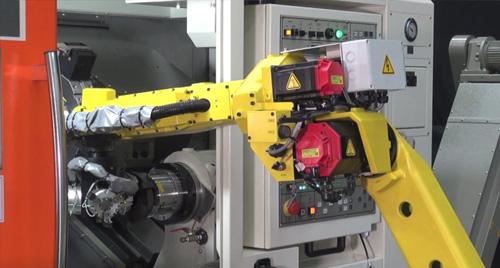

Joint Robot Automated System #

A flexible processing unit tailored for workpieces requiring both lathe and machining center operations. The joint robot handles loading and unloading, facilitating future expansion. The system can be equipped with a fourth axis, automatic hydraulic fixtures, and supports multi-process automation.

System Components:

- Vturn-A20SM Main and Sub-Spindle Lathe + Vcenter-P76 Machining Center

- Joint Robot

- Automatic Material Supply Table

High-Performance Automated Processing System (Series 2): Two Small Lathes Vturn-NP16 + Robot Arm #

- Latest model with a compact width and small footprint.

- Off-machine measurement and correction reduce manual intervention and increase utilization.

- Two machines share a measuring instrument and material supply table, optimizing investment.

System Components:

- Latest Model Small Width CNC Lathe Vturn-NP16 x2

- Gantry Robot

- Automatic Material Supply Table

- Off-Machine Measurement System: Balance VM25

- Finished Product Conveyor

Super Vcenter AX 630 5-Axis Machining Center + Multi-Pallet Storage + Tower Tool Magazine #

The Super Vcenter-AX630 features an optimized structure and a high-speed, high-rigidity axial feeding system. Its B/C axes use a roller cam mechanism for superior dynamic and static rigidity. Intelligent functions and multiple sensors throughout the machine contribute to energy savings and environmental sustainability.

Multi-Pallet Storage:

- Circular rack structure utilizes vertical space, reducing the system footprint.

- The material waiting area doubles as finished product storage, simplifying inspection.

- Integrated work order management and production scheduling save time and reduce logistics costs.

Tower Tool Magazine:

- Circular rack structure for space efficiency.

- Six pre-set tool holders enable tool changes without waiting during processing.

- Visualized tool management system displays all tool information.

System Components:

- Super Vcenter AX 630 5-Axis Machining Center

- Multi-Pallet Storage

- Tower Tool Magazine

Intelligent Aluminum Wheel Processing System #

System Components:

- Vturn-V22W Vertical Lathe

- Vturn-V22WT2 Vertical Lathe

- Vcenter-22W Vertical Milling Machine

- Robot Arm

- Aluminum Wheel Infeed System

- Infeed CCD Visual Inspection System

- Aluminum Wheel Cleaning Machine

- Valve Hole Angle Correction

- CCD Visual Inspection System

- Aluminum Wheel Outfeed System

- SCADA + Production Scheduling

Proprietary Software Functions #

- Flexible Scheduling System: Adjusts processing procedures based on equipment layout.

- Production History Management: Records serial numbers and quality data, outputs to aluminum wheels via laser engraving.

- SCADA Monitoring System: Modular design supports expansion for various processing industries.

- Process Control: Calculates CPK values using quality data from inspection equipment.

- Inspection System: Supports multiple quality inspection functions, with options for visual or contact-type measurement systems.

Vturn-A200 Horizontal Lathe + Collaborative Robot Arm

Vturn-A200 Horizontal Lathe + Collaborative Robot Arm Vturn-F26 Fighter Lathe + Collaborative Robot Arm

Vturn-F26 Fighter Lathe + Collaborative Robot Arm High-Performance Automated Processing System (Series 1)

High-Performance Automated Processing System (Series 1) Regional Type Elbow Joint Robot Flexible Processing Unit

Regional Type Elbow Joint Robot Flexible Processing Unit Joint Robot Automated System

Joint Robot Automated System High-Performance Automated Processing System (Series 2)

High-Performance Automated Processing System (Series 2) Super Vcenter AX 630 5-Axis Machining Center

Super Vcenter AX 630 5-Axis Machining Center AX630 System

AX630 System Intelligent Aluminum Wheel Processing System

Intelligent Aluminum Wheel Processing System