Integrating Management and Technology for Smart Manufacturing #

Onward Rise: Management Thinking Meets Technology Integration #

Victor Taichung’s approach to intelligent equipment is rooted in the synergy between management strategies and technological advancements. The goal is to enhance overall corporate operational value and address key pain points in manufacturing.

Management Objectives #

- Zero Accidents

- Zero Losses

- Zero Failures

- Zero Defects

Technology Integration #

Victor Taichung’s intelligent assembly and processing lines leverage:

- Big Data Collection, Visualization, and Diagnostic Systems

- Health Check Systems

- Custom App Development

- IoT Network Layer

- Perception Layer (Sensors, Image Vision, etc.)

- Equipment Layer (Intelligent Machine Tools, Robots, Peripheral Equipment)

Purpose of Victor Taichung Development V4.0 #

- Begin with the end in mind, creating value for customers

- Provide integrated intelligent automation system technology

Key Functionalities #

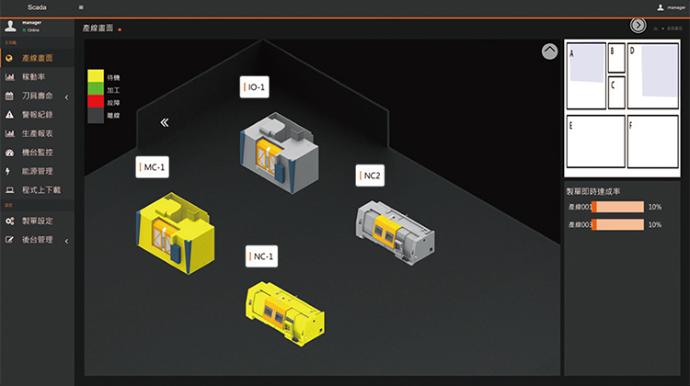

1. Equipment Status Monitoring & Process Management #

Monitor real-time equipment status and manage processes efficiently.

2. Health Check, Predictive Maintenance & Power Monitoring #

Implement health checks and predictive maintenance services, including power consumption analysis.

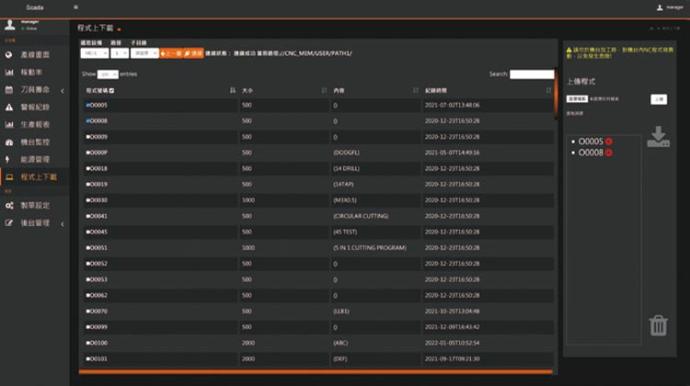

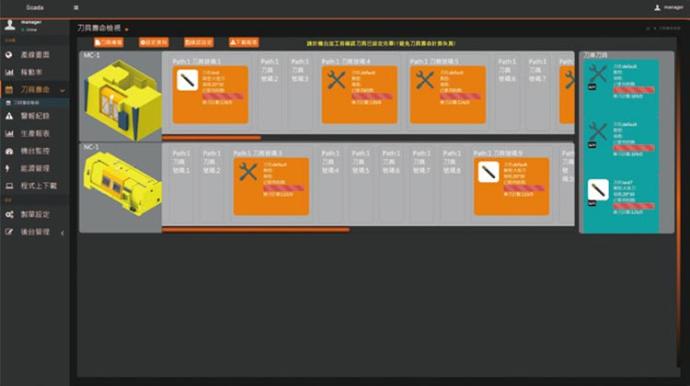

3. Machining Program, Tool, and Tool Life Management #

Manage machining programs and tools, track tool life, and receive alerts for tool replacement.

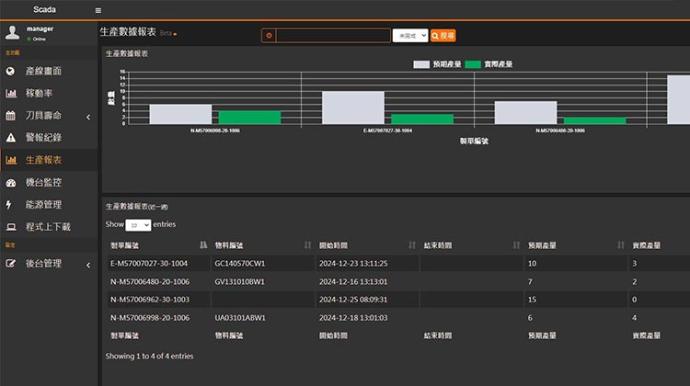

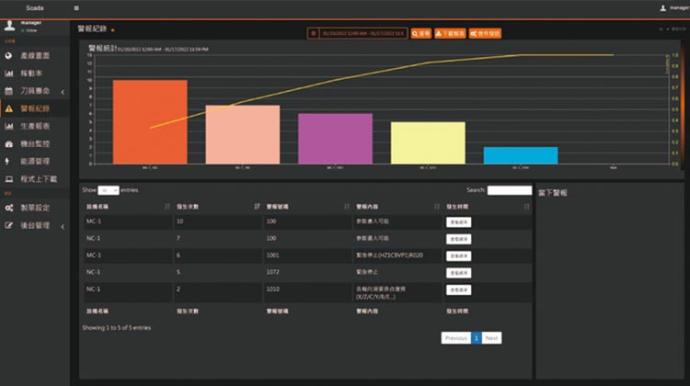

4. Operation Management, Performance, and Fault History #

Track operational performance and maintain comprehensive fault history records.

5. Big Data Collection and Analysis #

Collect and analyze production data to drive continuous improvement.

Victor Taichung Smart Box #

- Automatic data collection for real-time production insights

- Full-plant monitoring and utilization management

- Equipment alarm history and data records

- OEE (Overall Equipment Efficiency) integration for production tracking

- Real-time health status and abnormality reporting

- Minimize downtime and resource waste, improve efficiency

Main Features #

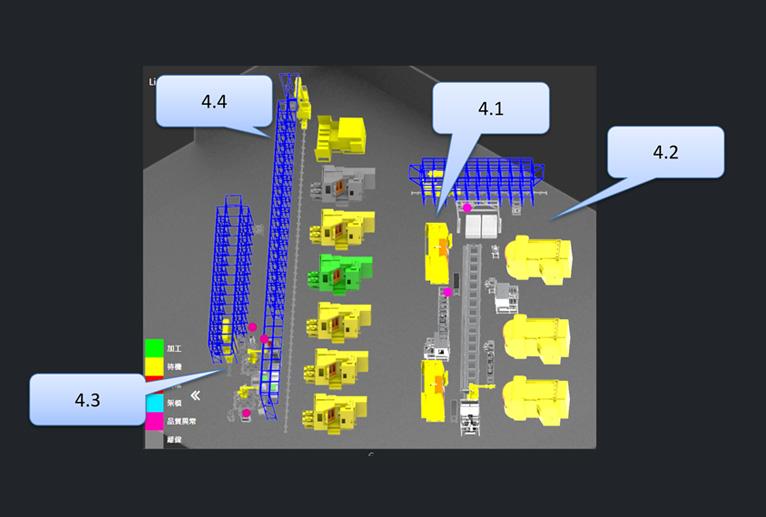

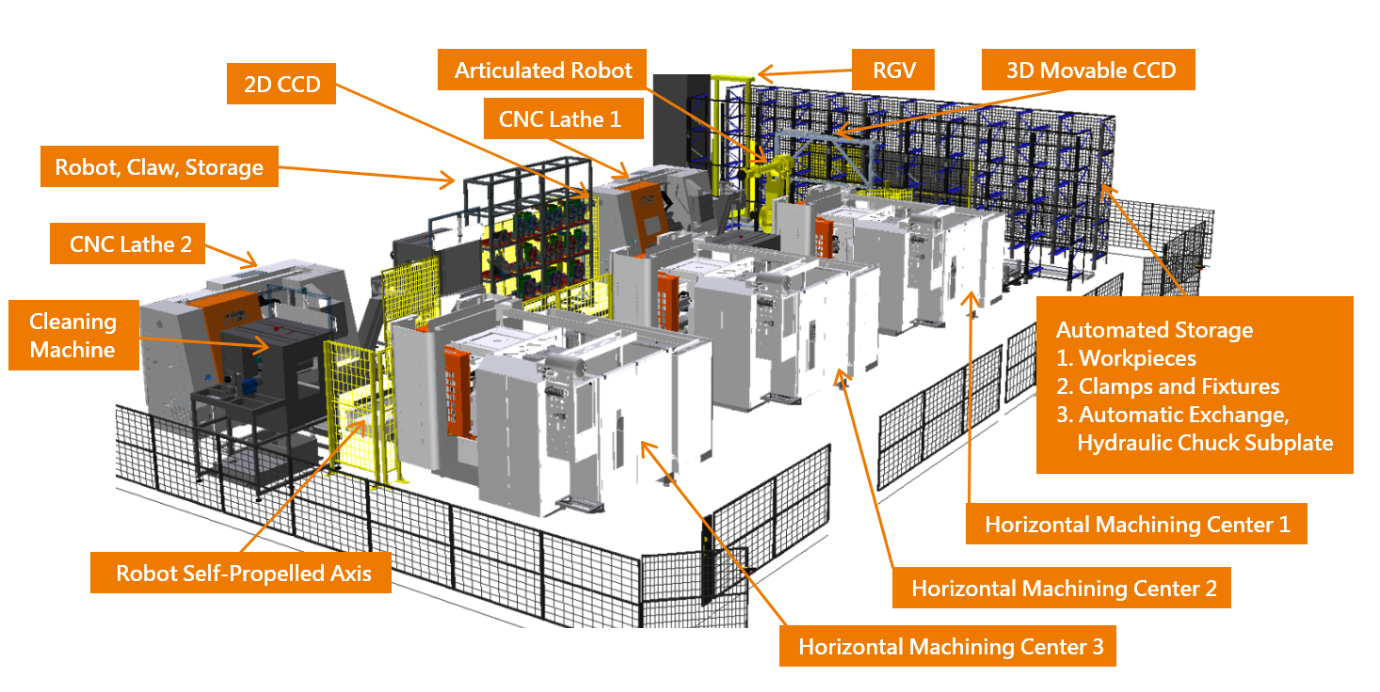

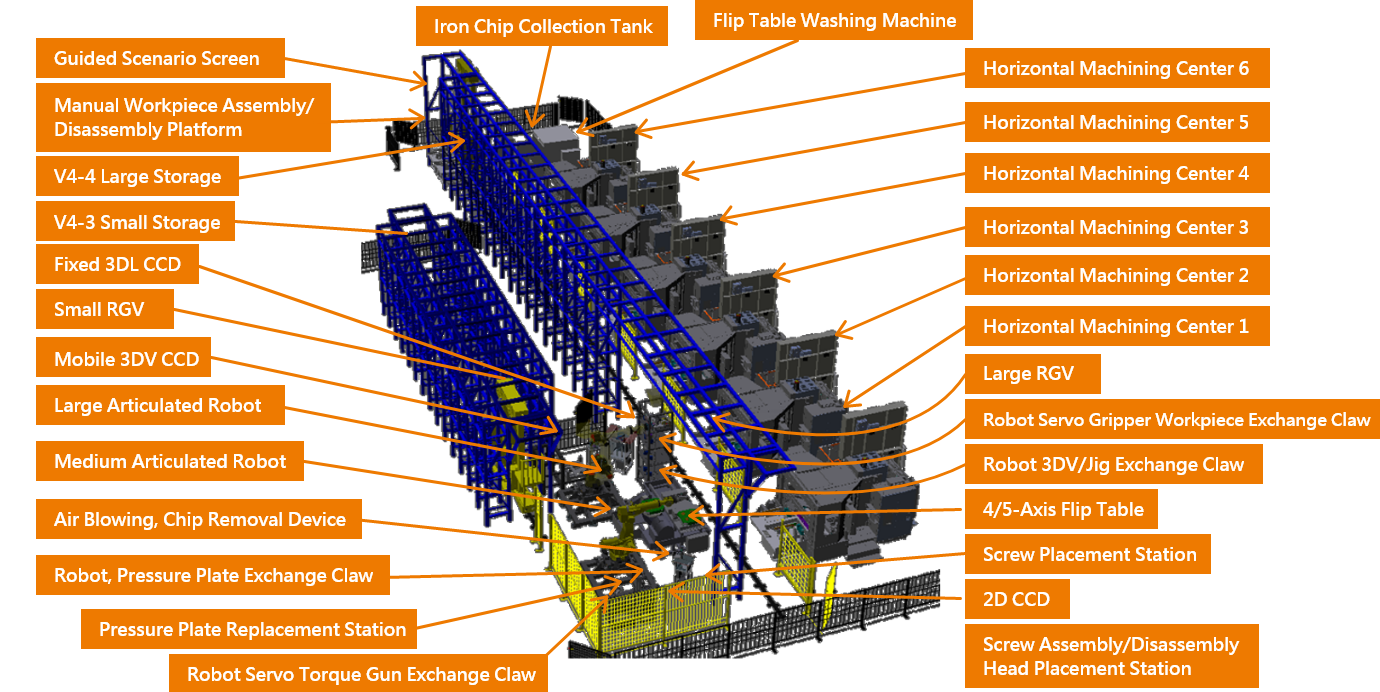

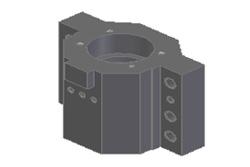

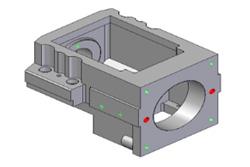

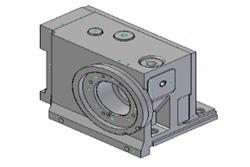

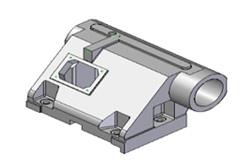

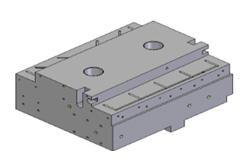

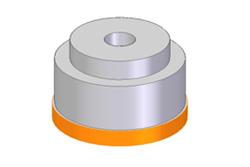

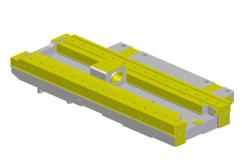

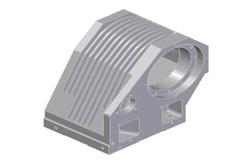

3D Diagrams: V4.1~V4.4 #

Efficiency and Workpiece Diversity #

- Optimized for single-piece processing and different specifications for each part

- Supports 155 types of workpieces across V4.1 to V4.4

Workpiece Types by System #

4.1 Workpiece 1

4.1 Workpiece 1

4.1 Workpiece 2

4.1 Workpiece 2

4.1 Workpiece 3

4.1 Workpiece 3

4.2 Workpiece 1

4.2 Workpiece 1

4.2 Workpiece 2

4.2 Workpiece 2

4.3 Workpiece 1

4.3 Workpiece 1

4.3 Workpiece 2

4.3 Workpiece 2

4.3 Workpiece 3

4.3 Workpiece 3

4.3 Workpiece 4

4.3 Workpiece 4

4.3 Workpiece 5

4.3 Workpiece 5

4.4 Workpiece 1

4.4 Workpiece 1

4.4 Workpiece 2

4.4 Workpiece 2

Summary of Advantages #

- Flexible production for small batches and diverse specifications

- Advanced vision and automation applications

- Self-developed software for scheduling and SCADA

- Integrated hardware and software for seamless operation

- Predictive mechanisms to prevent system failures

- Centralized management of chips, fluids, and oil mist

- Guided installation systems for complex workpieces

For more details and videos, visit the Intelligent Equipment page.